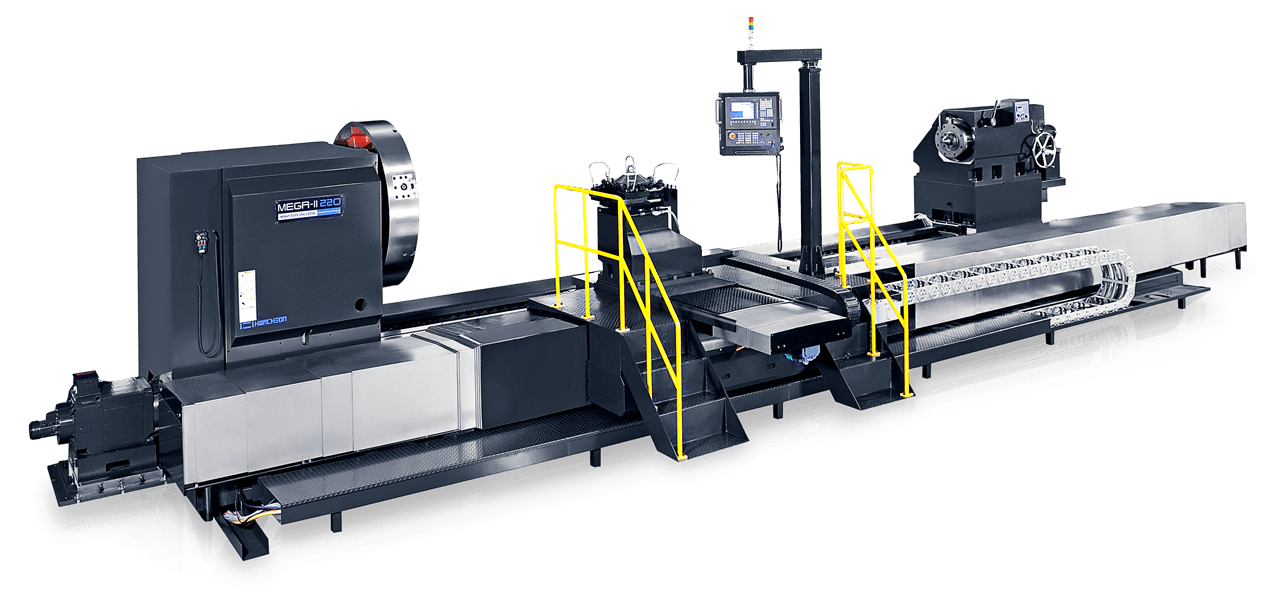

MEGAII-260 ensures stable and powerful machining based on a high rigidity box way type feed system and an integrated bed structure, and maintains high precision even during long-term machining by minimizing thermal displacement.

MEGAII-260 ensures stable and powerful machining based on a high rigidity box way type feed system and an integrated bed structure, and maintains high precision even during long-term machining by minimizing thermal displacement.

Machine Specification

| Item | MEGAII-260 | |||||

|---|---|---|---|---|---|---|

| 6000 | 8000 | 10000 | 12000 | 17000 | ||

| Capacity | ||||||

| Swing over bed | mm | Ø2,650 | Ø2,650 | Ø2,650 | Ø2,650 | Ø2,650 |

| Swing over Saddle | mm | Ø2,200 | Ø2,200 | Ø2,200 | Ø2,200 | Ø2,200 |

| Max. Cutting Dia over Bed | mm | Ø2,600 | Ø2,600 | Ø2,600 | Ø2,600 | Ø2,600 |

| Max Cutting Diameter Over Saddle | mm | Ø2,200 | Ø2,200 | Ø2,200 | Ø2,200 | Ø2,200 |

| Distance between centers | mm | 6,000 | 8,000 | 10,000 | 12,000 | 17,000 |

| Max. Loading Capacity | kgf | 25,000 (Opt.: 40,000) | 25,000 (Opt.: 40,000) | 25,000 (Opt.: 40,000) | 25,000 (Opt.: 40,000) | 25,000 (Opt.: 40,000) |

| Chuck Size | inch | 63 | 63 | 63 | 63 | 63 |

| Spindle | ||||||

| Spindle Bore Diameter | mm | – | – | – | – | – |

| Type of Spindle Nose | – | Special (Ø300 x 280) | Special (Ø300 x 280) | Special (Ø300 x 280) | Special (Ø300 x 280) | Special (Ø300 x 280) |

| Max Spindle Speed | rpm | 1 ~ 130 | 1 ~ 130 | 1 ~ 130 | 1 ~ 130 | 1 ~ 130 |

| Spindle Taper | – | Special | Special | Special | Special | Special |

| Spindle Torque | kgf.m | 12,713 | 12,713 | 12,713 | 12,713 | 12,713 |

| Number of spindle speed | step | Auto 3 steps [40,000 kg : Auto 2 steps] | Auto 3 steps [40,000 kg : Auto 2 steps] | Auto 3 steps [40,000 kg : Auto 2 steps] | Auto 3 steps [40,000 kg : Auto 2 steps] | Auto 3 steps [40,000 kg : Auto 2 steps] |

| Spindle Motor | kW | 136 / 92 | 136 / 92 | 136 / 92 | 136 / 92 | 136 / 92 |

| Turret | ||||||

| Turret | – | 4 Position Electric | 4 Position Electric | 4 Position Electric | 4 Position Electric | 4 Position Electric |

| Number of Tool Station | ea | 4 | 4 | 4 | 4 | 4 |

| Tool Size (Out Dia x Boring bar size) | mm | □40 × Ø60 (Opt.: □50 × Ø60) | □40 × Ø60 (Opt.: □50 × Ø60) | □40 × Ø60 (Opt.: □50 × Ø60) | □40 × Ø60 (Opt.: □50 × Ø60) | □40 × Ø60 (Opt.: □50 × Ø60) |

| Turret Size | mm | □440 | □440 | □440 | □440 | □440 |

| Axes | ||||||

| Rapid Traverse (X / Z) | mm/min | 4,000 / 6,000 | 4,000 / 6,000 | 4,000 / 6,000 | 4,000 / 6,000 | 4,000 / 6,000 |

| Max. Stroke (X / Z) | mm | 1,100 / 6,300 | 1,100 / 8,300 | 1,100 / 10,300 | 1,100 / 12,300 | 1,100 / 17,300 |

| Feed Motor (X / Z) | kW | 10.5 / 35.5 | 10.5 / 35.5 | 10.5 / 35.5 | 10.5 / 35.5 | 10.5 / 35.5 |

| Tailstock | ||||||

| Tailstock | – | Built-in type | Built-in type | Built-in type | Built-in type | Built-in type |

| Quill Diameter | mm | Ø450 (Opt.: Ø600) | Ø450 (Opt.: Ø600) | Ø450 (Opt.: Ø600) | Ø450 (Opt.: Ø600) | Ø450 (Opt.: Ø600) |

| 센터 형식 | – | Ø160 x 75° Dead Center | Ø160 x 75° Dead Center | Ø160 x 75° Dead Center | Ø160 x 75° Dead Center | Ø160 x 75° Dead Center |

| Tailstock Travel | mm | 300 | 300 | 300 | 300 | 300 |

| Bed | ||||||

| Bed Width | mm | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 |

| Bed Length | mm | 10,100 | 12,100 | 14,100 | 16,100 | 21,110 |

| Bed Type | – | 1 bed, 3 way | 1 bed, 3 way | 1 bed, 3 way | 1 bed, 3 way | 1 bed, 3 way |

| Motor | ||||||

| Coolant Pump | kW | 1,1 | 1,1 | 1,1 | 1,1 | 1,1 |

| Lubrication Pump (Bed / Spindle) | W | 57 / 750 | 57 / 750 | 57 / 750 | 57 / 750 | 57 / 750 |

| Tank Capacity | ||||||

| Coolant | ℓ | 700 | 700 | 700 | 700 | 700 |

| Power Source | ||||||

| Power Capacity | kVA | 200 | 200 | 200 | 200 | 200 |

| Power Specification | – | 380V, 60Hz | 380V, 60Hz | 380V, 60Hz | 380V, 60Hz | 380V, 60Hz |

| Machine Size | ||||||

| Height | mm | 3,725 | 3,725 | 3,725 | 3,725 | 3,725 |

| Floor Space (L x W) | mm | 13,500 x 4,200 | 15,500 x 4,200 | 17,500 x 4,200 | 19,500 x 4,200 | 24,500 x 4,200 |

| Weight | Kgf | 81,000 | 86,000 | 91,000 | 96,000 | 110,000 |

| NC Controller | – | SIEMENS 828D | SIEMENS 828D | SIEMENS 828D | SIEMENS 828D | SIEMENS 828D |