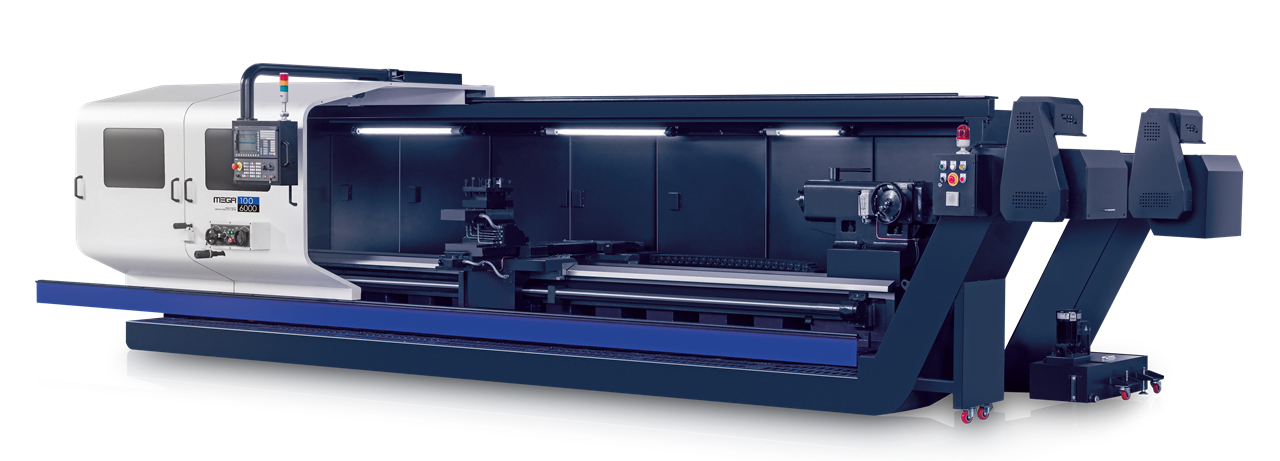

MEGA-100 is a flatbed horizontal CNC lathe optimized for machining precision parts of shaft shape such as main shafts and large pipes in the fields of shipbuilding, wind power, aerospace and defense industries.

MEGA-100 ensures stable and powerful machining based on a high rigidity box way type feed system and an integrated bed structure, and maintains high precision even during long-term machining by minimizing thermal displacement.

Machine Specification

| Item | MEGA-100 | ||||

|---|---|---|---|---|---|

| 3000 | 4000 | 5000 | 6000 | ||

| Capacity | |||||

| Swing over bed | mm | Ø1,080 | Ø1,080 | Ø1,080 | Ø1,080 |

| Swing over Saddle | mm | Ø720 | Ø720 | Ø720 | Ø720 |

| Max. Cutting Dia over Bed | mm | Ø1,000 [12 Position Electric : Ø830] [12 Position Turnmill : Ø500] | Ø1,000 [12 Position Electric : Ø830] [12 Position Turnmill : Ø500] | Ø1,000 [12 Position Electric : Ø830] [12 Position Turnmill : Ø500] | Ø1,000 [12 Position Electric : Ø830] [12 Position Turnmill : Ø500] |

| Max Cutting Diameter Over Saddle | mm | Ø700 [12 Position Turnmill : Ø500] | Ø700 [12 Position Turnmill : Ø500] | Ø700 [12 Position Turnmill : Ø500] | Ø700 [12 Position Turnmill : Ø500] |

| Distance between centers | mm | 3,000 | 4,000 | 5,000 | 6,000 |

| Max. Loading Capacity (Tailstock Support (O / X)) | kgf | 5,000 / 1,000 | 5,000 / 1,000 | 5,000 / 1,000 | 5,000 / 1,000 |

| Chuck Size | inch | 18 | 18 | 18 | 18 |

| Spindle | |||||

| Spindle Bore Diameter | mm | Ø155 (Opt.: Ø255 / Ø 320) | Ø155 Ø255 / Ø 320 | Ø155 Ø255 / Ø 320 | Ø155 Ø255 / Ø 320 |

| Type of Spindle Nose | ASA | A2-15 [Ø320 : A2-20] | A2-15 [Ø320 : A2-20] | A2-15 [Ø320 : A2-20] | A2-15 [Ø320 : A2-20] |

| Max Spindle Speed | rpm | 40~750 [Ø255 : 30~650] [Ø320 : 20~400] | 40~750 [Ø255 : 30~650] [Ø320 : 20~400] | 40~750 [Ø255 : 30~650] [Ø320 : 20~400] | 40~750 [Ø255 : 30~650] [Ø320 : 20~400] |

| Spindle Taper | M.T | No.170 [Ø255 : No.260] [Ø320 : -] | No.170 [Ø255 : No.260] [Ø320 : -] | No.170 [Ø255 : No.260] [Ø320 : -] | No.170 [Ø255 : No.260] [Ø320 : -] |

| Number of spindle speed | step | Auto 3 steps | Auto 3 steps | Auto 3 steps | Auto 3 steps |

| Spindle Motor | kW | 23 / 18.5 [FANUC : 22 / 18.5] | 23 / 18.5 [FANUC : 22 / 18.5] | 23 / 18.5 [FANUC : 22 / 18.5] | 23 / 18.5 [FANUC : 22 / 18.5] |

| Turret | |||||

| Turret | – | 4 Position Manual (Opt.: 4 Position Hydraulic) (Opt.: 12 Position Electric) (Opt.: 12 Position Turnmill) | 4 Position Manual (Opt.: 4 Position Hydraulic) (Opt.: 12 Position Electric) (Opt.: 12 Position Turnmill) | 4 Position Manual (Opt.: 4 Position Hydraulic) (Opt.: 12 Position Electric) (Opt.: 12 Position Turnmill) | 4 Position Manual (Opt.: 4 Position Hydraulic) (Opt.: 12 Position Electric) (Opt.: 12 Position Turnmill) |

| Number of Tool Station | ea | 4 [전동 12각 : 12] [12 Position Turnmill : 12] | 4 [전동 12각 : 12] [12 Position Turnmill : 12] | 4 [전동 12각 : 12] [12 Position Turnmill : 12] | 4 [전동 12각 : 12] [12 Position Turnmill : 12] |

| Tool Size (Out Dia x Boring bar size) | mm | □32 × Ø60 | □32 × Ø60 | □32 × Ø60 | □32 × Ø60 |

| Axes | |||||

| Rapid Traverse (X / Z) | mm/min | 6,000 / 6,000 | 6,000 / 6,000 | 6,000 / 6,000 | 6,000 / 5,000 |

| Max. Stroke (X / Z) | mm | 520 / 3,000 [전동 12각 : 415 / 3,000] [12 Position Turnmill : 250 / 3,000] | 520 / 4,000 [전동 12각 : 415 / 4,000] [12 Position Turnmill : 250 / 4,000] | 520 / 5,000 [전동 12각 : 415 / 5,000] [12 Position Turnmill : 250 / 5,000] | 520 / 6,000 [전동 12각 : 415 / 6,000] [12 Position Turnmill : 250 / 6,000] |

| Feed Motor (X / Z) | kW | 3.3 / 5.24 [FANUC : 3.0 / 4.0] | 3.3 / 5.24 [FANUC : 3.0 / 4.0] | 3.3 / 5.24 [FANUC : 3.0 / 4.0] | 3.3 / 9.58 [FANUC : 3.0 / 9.0] |

| Tailstock | |||||

| Tailstock | – | Built-in type | Built-in type | Built-in type | Built-in type |

| Quill Diameter | mm | Ø200 | Ø200 | Ø200 | Ø200 |

| Tailstock Center Taper | MT | No.6 | No.6 | No.6 | No.6 |

| 퀼 이송거리 | mm | 260 | 260 | 260 | 260 |

| Bed | |||||

| Bed Width | mm | 700 | 700 | 700 | 700 |

| Bed Length | mm | 5,370 | 6,370 | 7,370 | 8,370 |

| Bed Type | – | 1 bed, 2 way | 1 bed, 2 way | 1 bed, 2 way | 1 bed, 2 way |

| Motor | |||||

| Coolant Pump | W | 180 | 180 | 180 | 180 |

| Lubrication Pump (Bed / Spindle) | W | 57 / 200 | 57 / 200 | 57 / 200 | 57 / 200 |

| Tank Capacity | |||||

| Coolant | ℓ | 220 | 270 | 320 | 370 |

| Power Source | |||||

| Power Capacity | kVA | 45 | 45 | 45 | 45 |

| Power Specification | – | 380V, 60Hz [FANUC : 220V, 60Hz] | 380V, 60Hz [FANUC : 220V, 60Hz] | 380V, 60Hz [FANUC : 220V, 60Hz] | 380V, 60Hz [FANUC : 220V, 60Hz] |

| Machine Size | |||||

| Height | mm | 2,150 | 2,150 | 2,150 | 2,150 |

| Floor Space (L x W) | mm | 6,200 x 2,350 | 7,200 x 2,350 | 8,200 x 2,350 | 9,200 x 2,350 |

| Weight | Kgf | 11,500 | 13,000 | 14,500 | 16,000 |

| NC Controller | – | SIEMENS 828D (Opt.: FANUC 0i-TF Plus) | SIEMENS 828D (Opt.: FANUC 0i-TF Plus) | SIEMENS 828D (Opt.: FANUC 0i-TF Plus) | SIEMENS 828D (Opt.: FANUC 0i-TF Plus) |