Hi-TECH 700 provides a rigid and stable heavy duty cutting based on a highly rigid box-way feed structure designed with an air-floating system and bed structure while maintains high precision even during long-term processing by minimizing thermal displacement

Hwacheon software installed on the machine improves productivity and precision, provides better machining quality compared to existing machines.

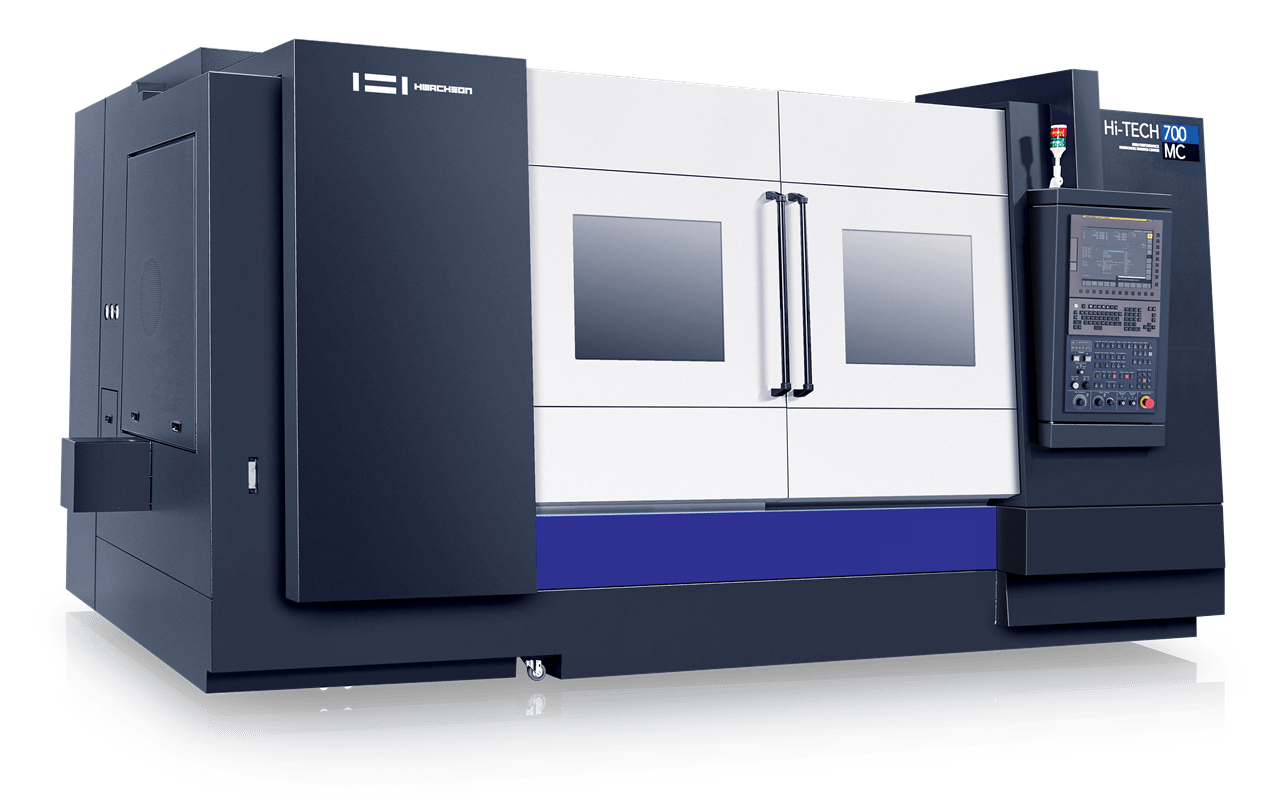

Machine Specification

| Item | Hi-TECH 700 | ||

|---|---|---|---|

| Hi-TECH 700 | Hi-TECH 700 MC | ||

| Swing over bed | mm | Ø900 | Ø900 |

| Max Cutting Diameter | mm | Ø680 | Ø680 |

| Standard Cutting Diameter | mm | Ø387 | Ø387 |

| Max Cutting Length | mm | 1,986 | 1,866 |

| Chuck Size (Main) | inch | 15 | 15 |

| Spindle | |||

| Type of Spindle Nose | ASA | A2-11 | A2-11 |

| Max Spindle Speed | rpm | 1,800 | 1,800 |

| Through Spindle Hole Diameter | mm | Ø132 | Ø132 |

| Max Bar Size | mm | Ø116 | Ø116 |

| Spindle Bearing Inner Diameter | mm | Ø180 | Ø180 |

| Spindle Motor | kW | 37 / 30 | 37 / 30 |

| Turret | |||

| Number of Tool Station | ea | 12 | 12 |

| Tool Size (Out Dia x Boring bar size) | mm | □32 × Ø60 | □32 × Ø60 |

| Turret Indexing Time | sec/step | 0.4 | 0.4 |

| Axes | |||

| Rapid Traverse (X / Z) | m/min | 18 / 18 | 18 / 18 |

| Max. Stroke (X / Z) | mm | 360 / 2,050 | 360 / 2,050 |

| Feed Motor (X / Z) | kW | 6 / 6 | 6 / 6 |

| Tailstock | |||

| Tailstock Stroke | mm | 1,878 | 1,878 |

| Cylinder Dia | mm | Ø150 | Ø150 |

| Quill Stroke | mm | 150 | 150 |

| Quill Taper | MT | # 5 | # 5 |

| Turnmill (Opt.) | |||

| Spindle Motor | kW | – | 7.5 / 5.5 |

| Max Spindle Speed | rpm | – | 2,000 |

| Max Drill/Tap Size (Endmill / Collet size) | mm | – | Ø32/ ER 50 |

| Min. Index Angle | deg | – | 0.0001 |

| Tank Capacity | |||

| Lubrication | ℓ | 12 | 12 |

| Hydraulic | ℓ | 50 | 50 |

| Coolant | ℓ | 300 | 300 |

| Power Sources | |||

| Electrical Power Supply | kVA | 75 | 75 |

| Machine Size | |||

| Height | mm | 2,535 | 2,535 |

| Floor Space (L x W) | mm | 5,065 x 2,282 | 5,065 x 2,282 |

| Weight | Kgf | 17,350 | 17,350 |

| NC Controller | – | Fanuc 0i-TF Plus | Fanuc 0i-TF Plus |